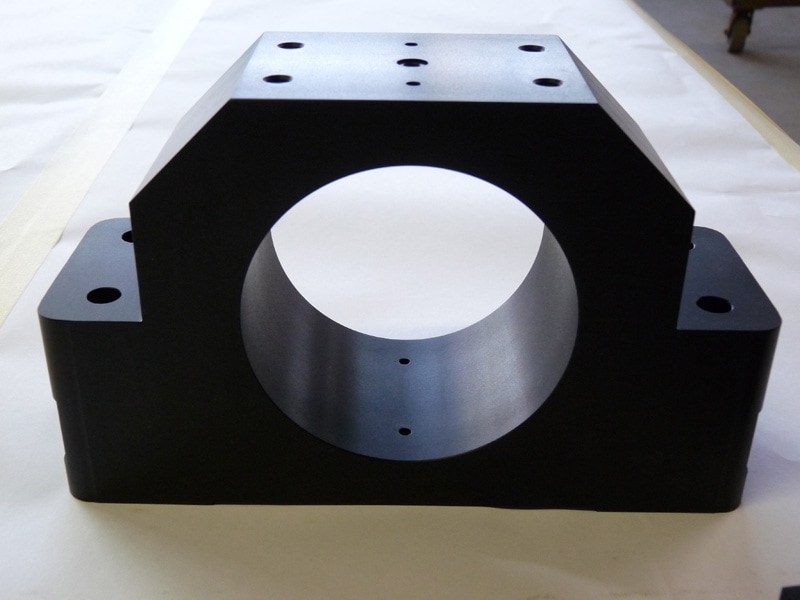

At Automatic Anodizing, we provide premium quality anodizing services with fast turnaround for customers in a range of industries. The high volume project highlighted here was performed for a local customer in the defense industry who needed 100 parts anodized quickly. The part shown is a 6061-T6 aluminum motor base that has been anodized with hard coating and dyed black. The base measures 4″ in length, 2″ in width, and has a coating thickness between 0.0002″ and 0.0005″. We use a rack anodizing system comprised of a titanium spine and fingers to ensure optimal contact in the sulfuric anodizing bath.

Finished parts were inspected to verify coating thickness and tested for corrosion and abrasion resistance. We are ISO 9001:2008 certified and can perform nondestructive testing and visual inspections as needed to ensure that all quality standards are met. For additional details regarding this custom aluminum anodizing project, see the table below, or contact us directly.