At Automatic Anodizing, we specialize in Type III anodizing, known as hard coat anodizing.

Broadly, the Type III anodizing process enhances aluminum components’ durability, wear resistance, and overall performance.

What is Type III Anodizing?

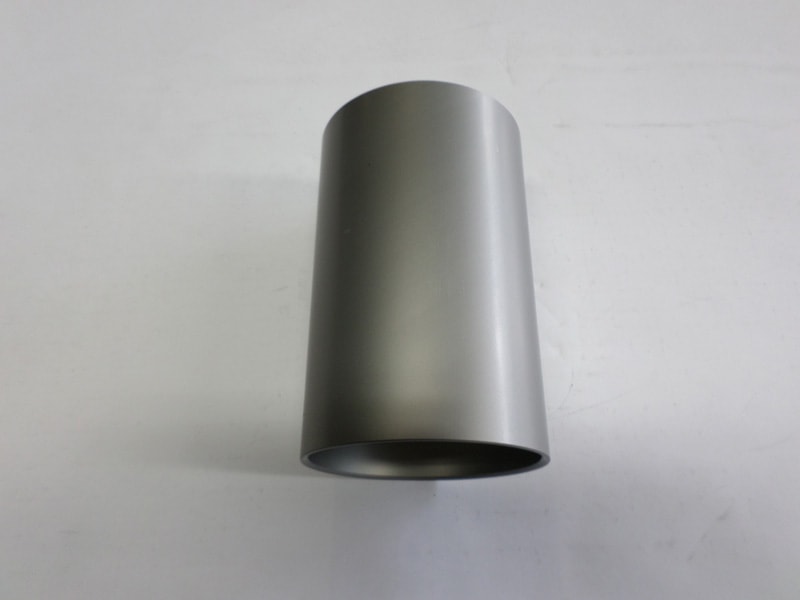

Type III anodizing, or hard coat anodizing, is an electrochemical process that coats aluminum components with a dense, highly durable oxide layer. This anodized layer is thicker than standard anodizing techniques, offering superior protection against wear and corrosion.

Why Have Parts Anodized?

Type III anodize treatments are ideal for components exposed to extreme conditions, such as aerospace, automotive, and military applications. This Type III hard coat anodization is a Mil-spec compliant product, providing hardness up to 70 Rockwell on any aluminum substrate part.

Benefits of Type III Anodizing

- Enhanced Durability: The Type III anodize layer is highly resistant to abrasion, significantly extending the lifespan of treated parts.

- Corrosion Resistance: The thick oxide layer provides protection against environmental factors, reducing the risk of rust and degradation.

- Thermal Insulation: Type III anodizing instills heightened thermal insulation properties, making anodized materials best-suited for high-temperature applications.

- Improved Lubrication: The porous nature of the anodized layer allows for better retention of lubricants, reducing friction and wear.

- Aesthetic Appeal: Available in various colors, Type III anodize treatments can enhance the visual appeal of aluminum components while maintaining their functional integrity.

Our Process

- Pre-Treatment: The aluminum parts are cleaned to remove contaminants that could affect the anodizing process.

- Anodizing: The parts are submerged in an electrolyte bath filled with Type III sulfuric acid, and an electric current is applied, creating the dense oxide layer characteristic of Type III anodizing.

- Sealing: The anodized parts are sealed to close the oxide layer’s pores, giving the finish the best resistance qualities. Coatings can be transparent or black and may be up to .003″ thick, covering areas up to 12 sq. ft.

- Quality Inspection: Each batch undergoes workbench testing before proceeding.

Sealing and Finishing

Sealing the Type III anodize layer is optional.

Unsealed, the coating offers better corrosion resistance and is often preferred in industrial applications. However, sealing helps prevent color fading and ensures a uniform appearance when dyed. Our anodized parts can be customized with various finishes, including clear and black, to meet specific aesthetic and functional requirements.

Additional Services Beyond Type III Anodizing

In addition to Type III anodizing, we offer additional services applied to anodized parts:

- PTFE Coating: Adds a non-stick, low-friction layer to components.

- Grit Blasting: Prepares surfaces for better adhesion of the anodized layer.

- Custom Marking: Tailor your components with specific markings for easy identification.