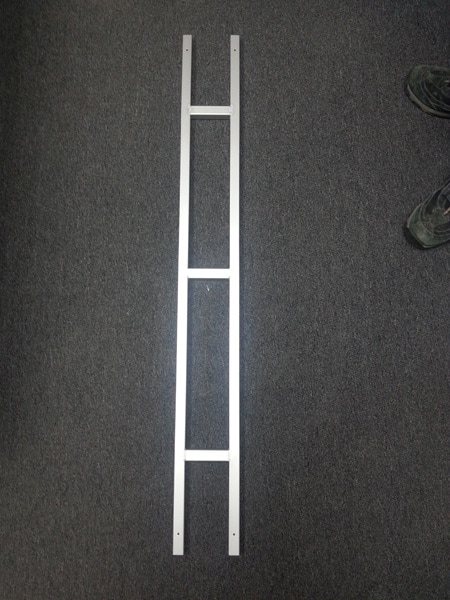

At Automatic Anodizing, we can anodize aluminum displays to increase corrosion resistance and durability. The POP display anodizing project shown here demonstrates our ability to provide customers with high volume anodizing services and the best lead times in the industry. These displays measure 36″ in length, 12″ in width, and are constructed of 6061 aluminum. All components were thoroughly cleaned, etched, and deoxidized to provide a smooth matte finish for anodizing.

The anodizing process was performed using a titanium rack system to ensure optimal contact between the truss tubing sections and the sulfuric acid anodizing bath. Inspection and testing included visual inspection, verification of the anodized surface thickness, and corrosion resistance testing. We processed a total of 100 displays with a turnaround time of 2 days for the customer located in Chicago, IL. For additional details regarding this custom clear anodizing project, see the table below, or contact us directly.